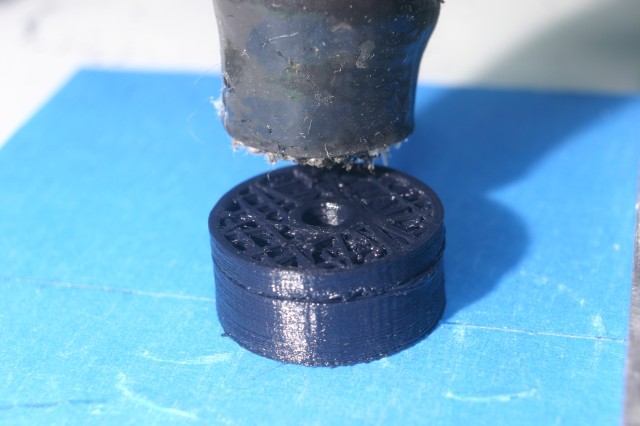

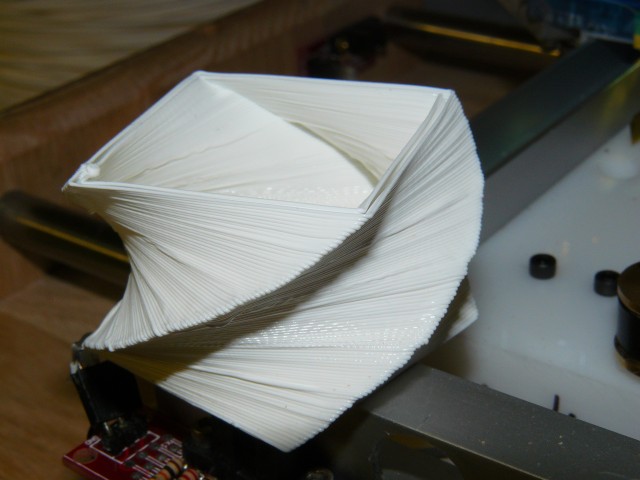

I did a test print at 0.08mm layers, the smallest layer height I’ve attempted yet.

I used a Makergear Plastruder, and black Ultimachine 4043D PLA.

Skeinforge sliced it onto 187 layers. It was not a fast print, taking about 2.5 hours.

Aside from a kind of smeary top layer, it came out ok.

Pictures follow:

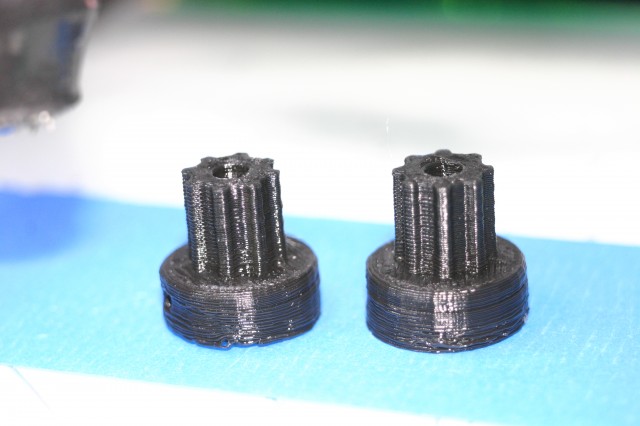

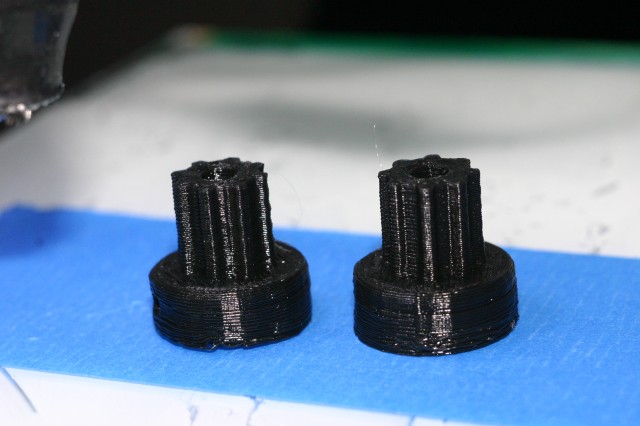

These two pulleys are the final print of a complete Prusa Mendel parts set I’ve been printing for a friend. It took about 3 weeks of evenings on & off. Most of the parts were printed one at a time, I didn’t use the production parts files.

The parts are now in the hands of Eric, hopefully he’ll be printing in a month or so.

Here’s some pictures.

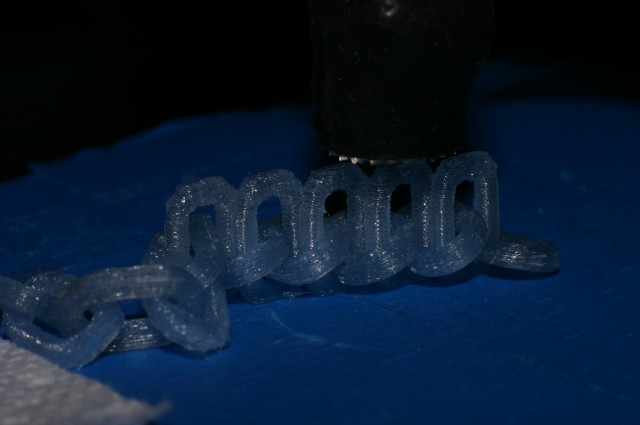

I made some links of chain, arranged just so that I could slip a previously printed link over two adjacent links, while they were still being printed. Purists may take exception, but I think it’s kind of cool.

The links were printed with a 0.4mm MakerGear nozzle, using 0.26mm layers. All the ‘extra shells’ settings in Skeinforge->Fill set to 0, the infill turned way down, and lots of cool air..

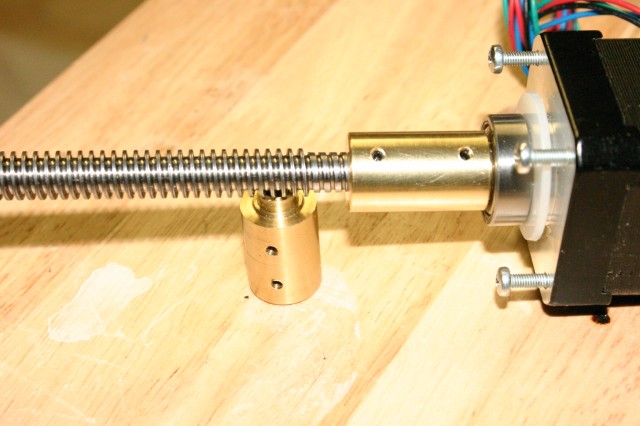

I made a new Z-axis motor coupler, as I suspect the old one was slightly off-center & causing wobbles to show in printed parts. The new one seems better, but I still have a little bit of wobble from a still undetermined source.

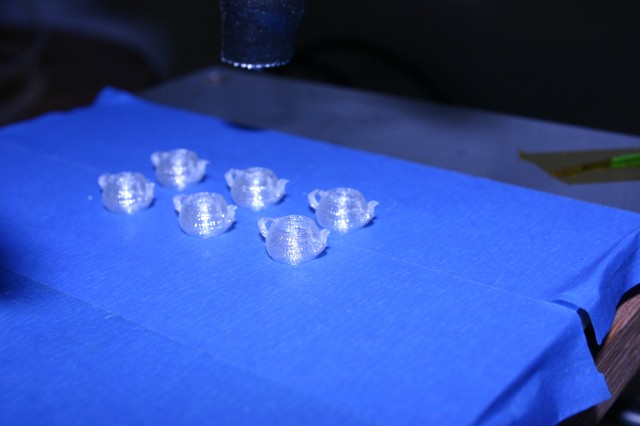

Here are a few recent prints. I recently started using the “Dimension” module within Skeinforge to retract the feed-stock between moves, and it’s really helped reduce the “stringies” that’d happen between parts.

These rings printed fine, but a few lost their grip right as the print finished.

I thought the firmware I’ve been using had PID temperature control, but it turns out it was using a simple on/off thermostat routine that caused the extruder temperature to have big variations.

Here are some prints of a RepRap Mendel part, basically a small cylinder. Due to the small size of the part quality really suffers as the temperature swings up & down.

The cylinder on the left was printed with the simple On/Off temperature control, and the two on the right were printed with a On / Medium control, that instead of turning the heater entirely off when the temperature exceeded it’s set limit, just set the heater to a medium value. It’s not a real fix, but it was simple to implement, and still makes a pretty significant difference.

The right-most part in this picture will probably be usable, but just barely.

Here are some larger parts that show the effect in the ‘banding’ you see every couple of layers, and the lower layers that are %100 solid internally, are a bit wider, which they should not be.

The code I changed isn’t *much* better, but it helps some, if you’re using the tonok-MMM firmware fork look at the file Tonokip_Firmware.pde in the manage_heater() function:

The original code was this:

if(current_raw >= target_raw) digitalWrite(HEATER_0_PIN,LOW);

else digitalWrite(HEATER_0_PIN,HIGH);

and I replaced it with this:

if (target_raw <= 50) {

analogWrite(HEATER_0_PIN,HEATER_0_OFF);

} else {

if(current_raw >= target_raw) {

analogWrite(HEATER_0_PIN,HEATER_0_LOW);

} else {

analogWrite(HEATER_0_PIN, HEATER_0_HIGH);

}

and added these lines to configuration.h:

const char HEATER_0_LOW = 85;

const char HEATER_0_HIGH = 255;

const char HEATER_0_OFF = 0;

The HEATER_0_LOW value should be a number in the 0-255 range that allows your heater to cool from your usual print temperature, be careful not to set it too high, or your nozzle will never cool down. As mine sits now it will idle at about 165C when the heater is on ‘Low’.

I’ve managed to connect a webcam to the ArduinoMega that is controlling my 3D printer, so now I can trigger a picture from the G-code that the printer is reading to make the part.

This means I can take a picture at the beginning of each printed layer, and make time-lapse video like this:

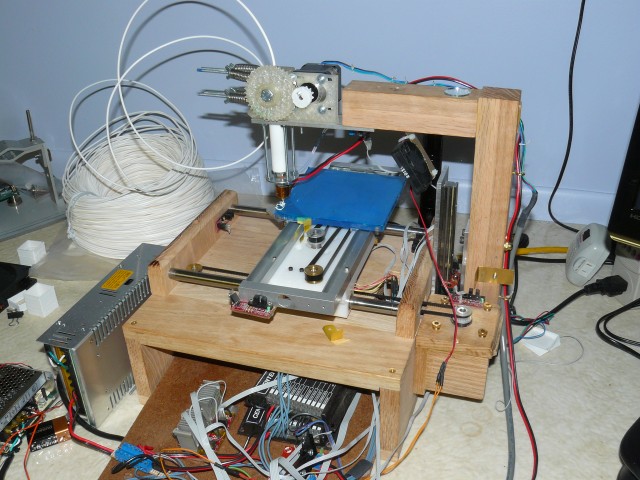

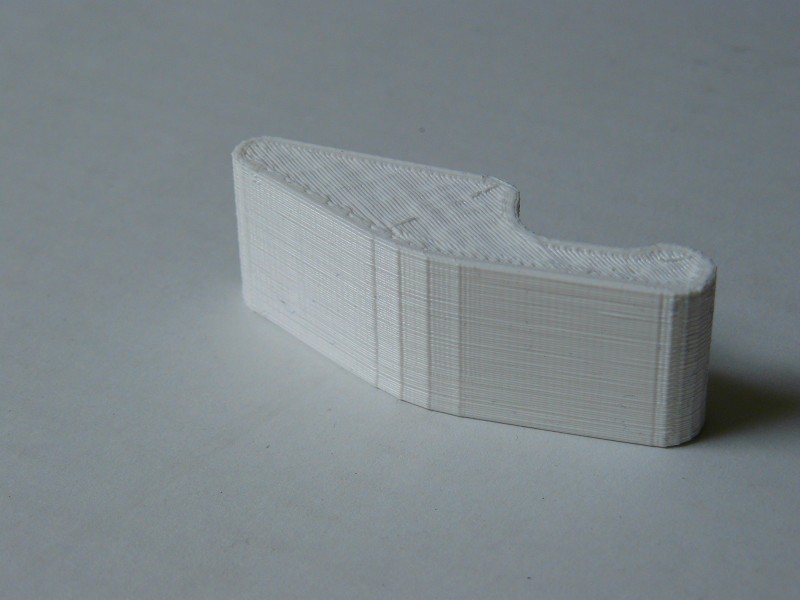

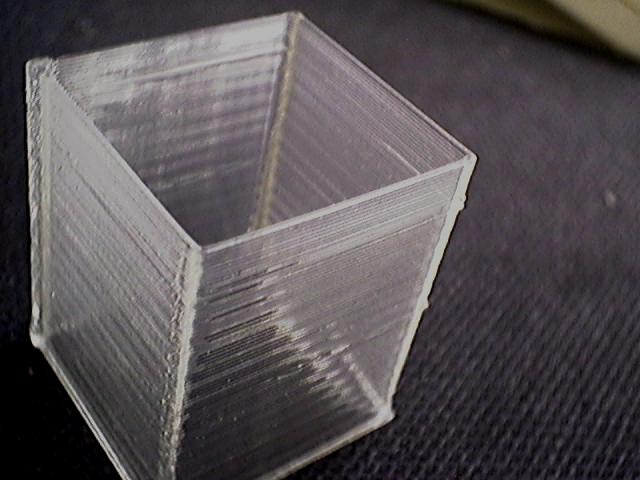

I’ve replaced my X axis, which was bronze bushings sliding on steel rod, with a recirculating-ball linear bearings and guide. The former X axis had enough play in it that you could feel it just by wiggling the print bed, and was affecting print quality quite a bit.

Between my new extruder hot-end, this new bearing, and lowering layer height to 0.36mm, I’m getting print quality that’s better than anything I’ve produced to date.

It’s also faster, so much faster that I’ve had the motor miss a few steps. I’m experimenting with feeding 24 volt power to the stepper motor drivers, and initial results seem good, although everything runs a bit warmer. I also have another linear bearing, and may use it on the Y axis.

Here’s a “before” picture of my previous X axis slide:

And here’s a picture of the new linear bearing & rail:

Here’s some of the first test prints I did with the new bearing:

Here is some video of it in action, if you listen carefully you can hear the *tick* *tick* *tick* *tick* of the ball-bearings clicking around their recirculating channels inside the carriage.

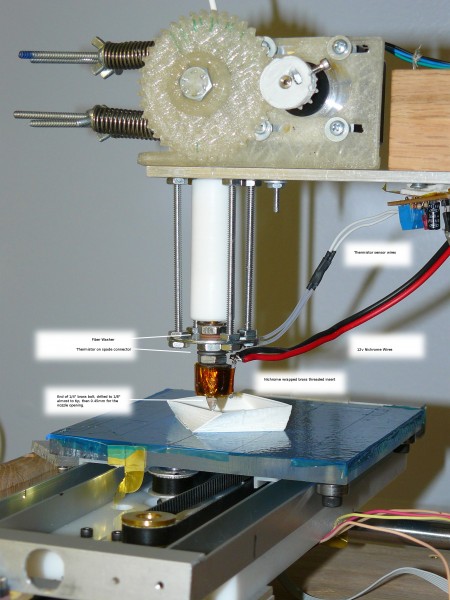

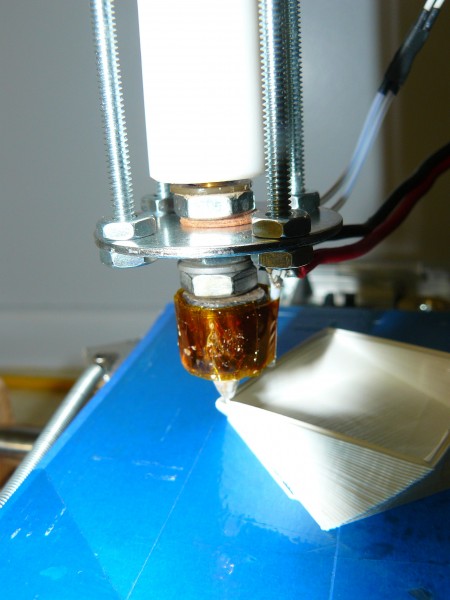

After melting the PTFE insulator yet another time, I’ve built another hot end. This one doesn’t use the PTFE as a stress-bearing part, but only to contain any plastic that may ooze above the top of the heater barrel.

The heater barrel is threaded into the PTFE about 0.25″, just enough to keep it aligned. The PTFE isn’t attached anywhere else, just sandwiched between the washer and the aluminum mounting plate above it.

I also made modular heater and thermistor, ala Makergear.com HeatCore. (I know a good idea when I steal it).

I’ve also ditched the separate nozzle, and used the brass screw as a one-part barrel+nozzle. The opening was drilled with a 0.45mm drill.

Print quality has improved by a lot, and I haven’t had any problems with the feed pinch-wheel teeth stripping the filament.

After trying to do some printing with a spool of White PLA 4042D, and being unable to replicate the quality level I’d got with Natural PLA 4042D, I started to look for possible differences in the composition of the filament.

After reading the datasheets, the only documented difference is %2-%4 pigment. I’d had decent results with green & black PLA, so I wasn’t convinced that the pigment was a factor. (Although at this point I was so frustrated that I wasn’t ruling it out, either).

I’ve printed so many single walled squares that I’m seeing them in my sleep.