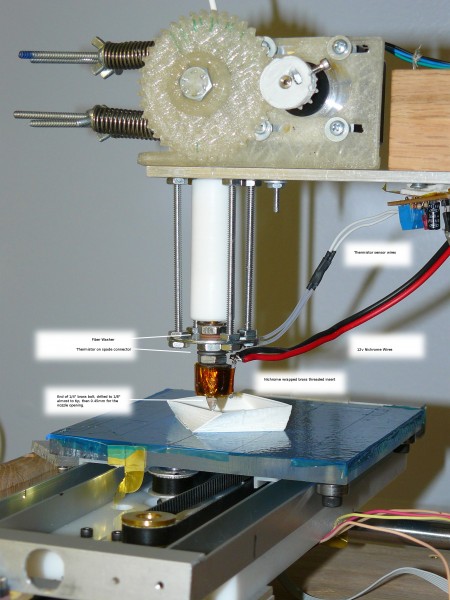

After melting the PTFE insulator yet another time, I’ve built another hot end. This one doesn’t use the PTFE as a stress-bearing part, but only to contain any plastic that may ooze above the top of the heater barrel.

The heater barrel is threaded into the PTFE about 0.25″, just enough to keep it aligned. The PTFE isn’t attached anywhere else, just sandwiched between the washer and the aluminum mounting plate above it.

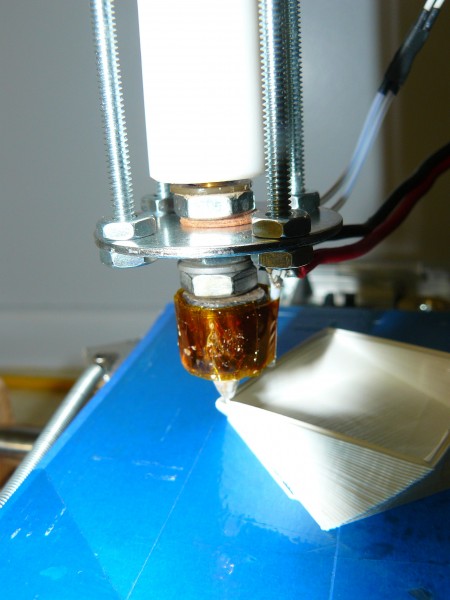

I also made modular heater and thermistor, ala Makergear.com HeatCore. (I know a good idea when I steal it).

I’ve also ditched the separate nozzle, and used the brass screw as a one-part barrel+nozzle. The opening was drilled with a 0.45mm drill.

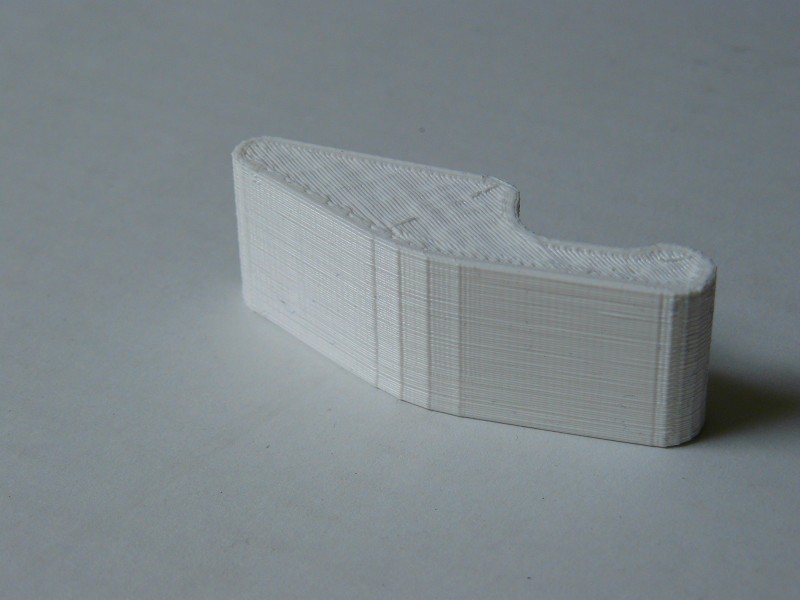

Print quality has improved by a lot, and I haven’t had any problems with the feed pinch-wheel teeth stripping the filament.