This is Van de Graff machine I built in 2006. It’s made of some plexiglass tube, and two mixing bowls.

The rollers are Delrin and teflon, as you want to use materials from opposite ends of the triboelectric scale.

The base is 1/2″ plastic that I heated with a torch and bent,

The rollers and the roller-support pieces were turned on my mini-lathe.

The axles are made of 8mm drill rod turning in skate bearings.

The belt is made from a piece of Theraband, basically a big sheet of rubber used for exercise. It’s glued into a loop with contact cement.

The motor is a surplus DC motor, powered by a 24v DC power supply. I think the power supply was originally for some part of a phone system, I picked it up at a local freight-salvage store.

I put an AC light dimmer inline to adjust the input power to the AC-adapter, which works pretty well to adjust the motor speed.

One problem I did run into was that all the static building up would cause arcing within the power supply, so I broke it open and insulated everything with silicone caulking. Probably not the best thing for the cooling, but I never really run it for more than a few minutes at a time, so I haven’t had any problems.

I built a mounting for the motor and speed control, but I don’t have any pictures of it, hopefully I’ll remember to take some.

Here’s a few pictures.

my Van de Graff generator, made from some junk I had.

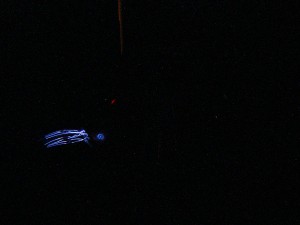

Here’s a picture of some sparks, this was a 15 second exposure, and the sparks arc up to two inches when it’s runnning well.

Long-exposure pic of Van de Graff discharges

Things that affect how well it works are mostly humidity, and how clean the ‘sphere’ is. Any dust causes sharp points where the electrons will ‘leak’ off, so for best results I’ll wipe it down first with some alcohol and a lint-free microfiber cloth, Supposedly it also helps to cook off any moisture by using a hair dryer, but I’ve never bothered to try that.

One more picture.

static electricity is hard to photograph