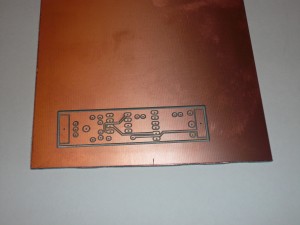

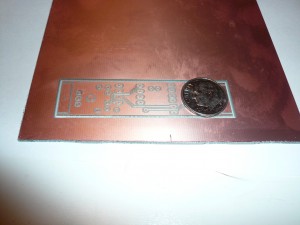

Last week I did a test pcb milling on my cnc pcb mill. I’m still learning how to properly configure the PCB-Gcode software, and I think this is the best result to date.

The board is the top side of LadyAda’s Drawdio board, and it took about 15 minutes to mill. I used a 60 degree pcb bit I got from a Chinese seller on eBay. Before drilling the holes I ran through the drilling gcode, once with the pcb bit still in the spindle, at a higher depth. Basicialy this drills shallow pilot holes through the copper, but not through the PCB. This helps reduce the amount of “walking” that the tiny drill bit does when it’s drilling the holes.

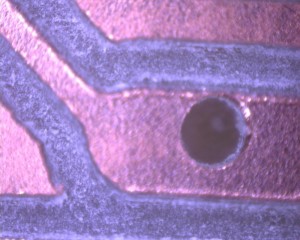

The holes are still off-center a bit from the pads, I’m still trying to figure out why that is. One possibility is that I accidentally twisted the router in it’s mounting when I changed from the pcb bit to the drill bit.

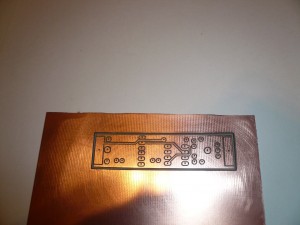

One more picture, after a little cleanup with some 1500 grit sandpaper, I think it came out pretty well.