I’ve replaced my X axis, which was bronze bushings sliding on steel rod, with a recirculating-ball linear bearings and guide. The former X axis had enough play in it that you could feel it just by wiggling the print bed, and was affecting print quality quite a bit.

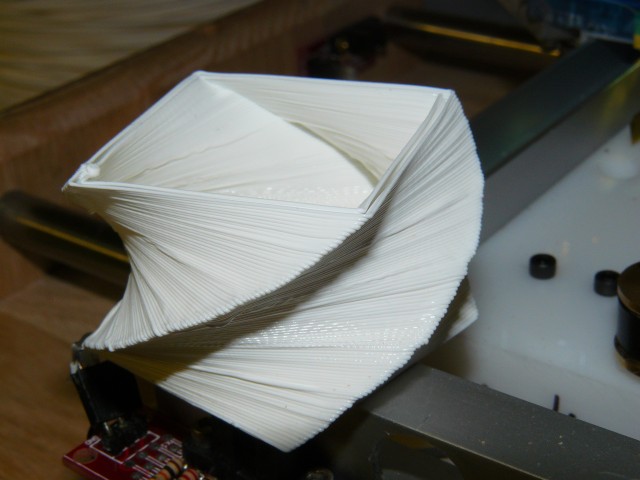

Between my new extruder hot-end, this new bearing, and lowering layer height to 0.36mm, I’m getting print quality that’s better than anything I’ve produced to date.

It’s also faster, so much faster that I’ve had the motor miss a few steps. I’m experimenting with feeding 24 volt power to the stepper motor drivers, and initial results seem good, although everything runs a bit warmer. I also have another linear bearing, and may use it on the Y axis.

Here’s a “before” picture of my previous X axis slide:

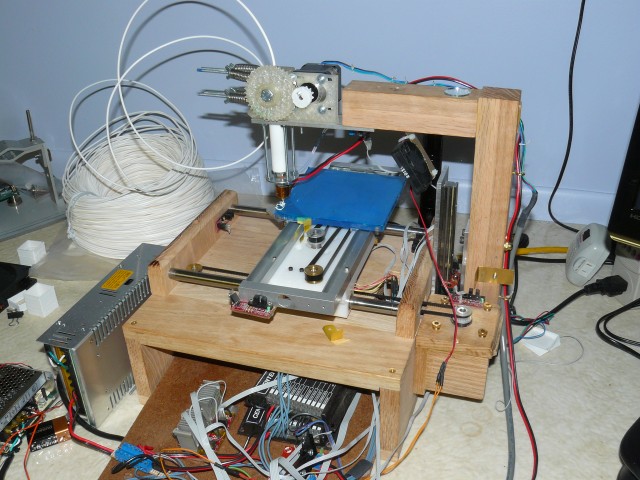

And here’s a picture of the new linear bearing & rail:

Here’s some of the first test prints I did with the new bearing:

Here is some video of it in action, if you listen carefully you can hear the *tick* *tick* *tick* *tick* of the ball-bearings clicking around their recirculating channels inside the carriage.