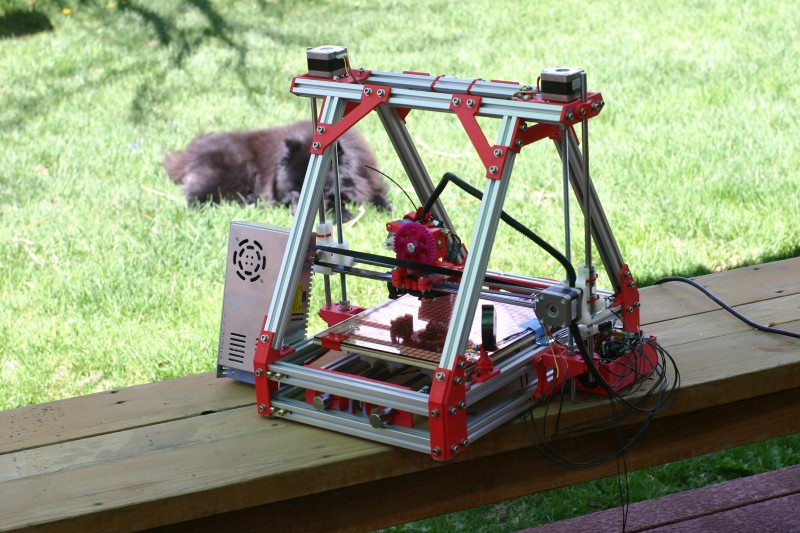

I’ve finished building a MendelMax 3D printer. The controller is a RAMPS 1.4 from Ultimachine, and the hot-end is a MakerGear plastruder, with a 0.25mm nozzle, pushing 1.7mm filament. I used the MendelMax “1.0″ parts, as the “1.5″ hadn’t been released when I started printing.

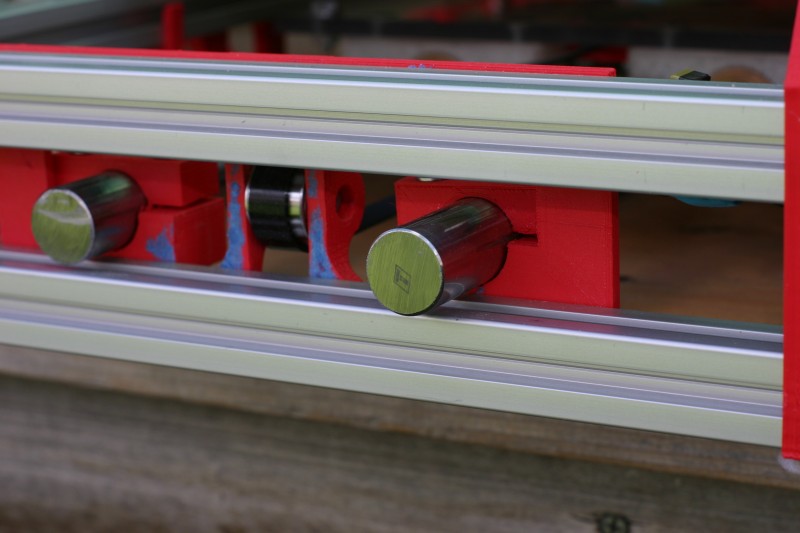

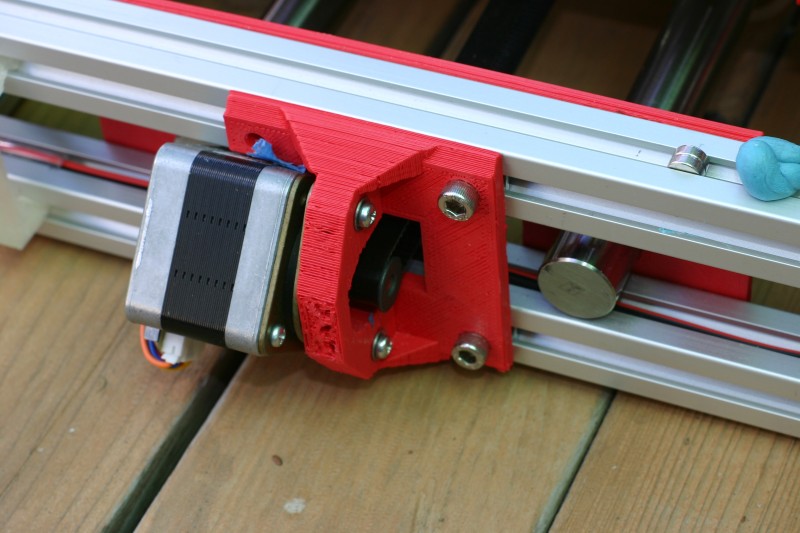

I strayed from the stock parts in a few places, most obvious being the 3/4″ Thomson linear shafts used for the Y axis, and the tapered Y-motor mounting.

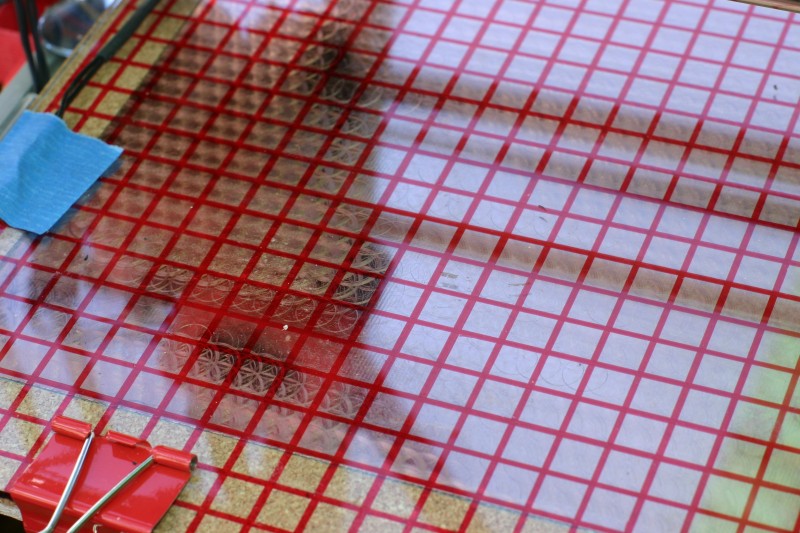

The print bed is a stack of 1/4″ plywood, a layer of cork insulation, a PCB Heater I milled, topped with glass from an old flatbed scanner. The glass has a grid of 1cm squares, applied with a red Sharpie and some CNC.

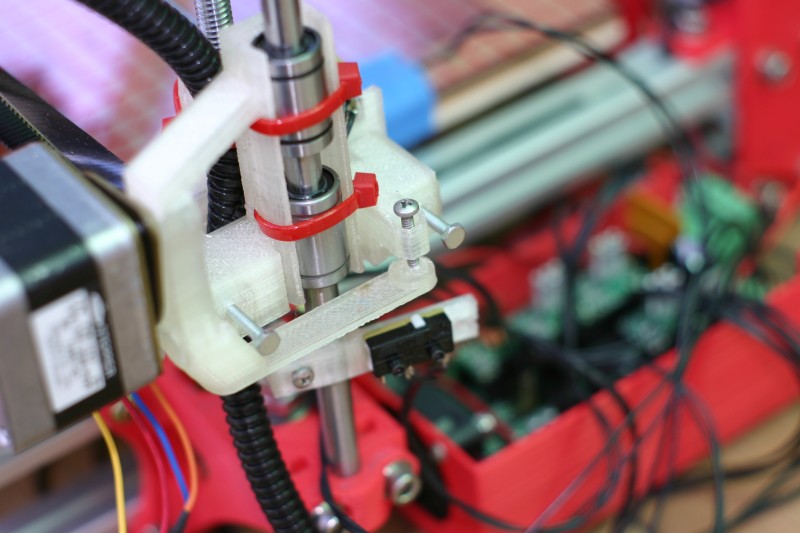

The X-Axis parts are the latest & greatest parts from Greg Frost, enabling full travel on the X axis, and a very-convenient Z-stop adjuster for homing. Bearings are cheap LM8UU on “X” and “Z”, and 3/4″ Oilite style bushings on “Y”.

Power comes from a generic “HS-350-12″ style power supply, mounted to the frame with two metal L-brackets. The supply drives the printer and PCB bed heater handily.

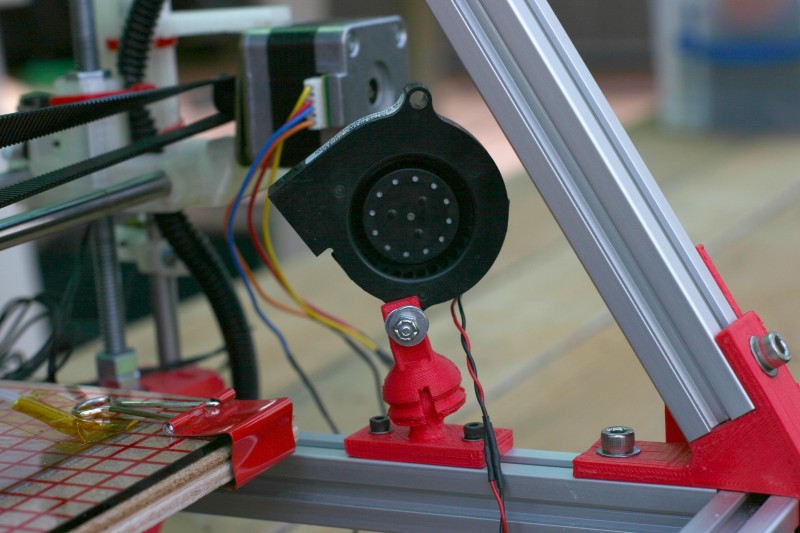

Since I print exclusively in PLA, I installed 2 blower fans, at opposite corners. The positioning of these fans can have a fairly dramatic effect on print quality, especially for parts with small details. The fans are wired to the controller, for automated fans control. I may still add 2 more fans.

Performance is good, I’ve managed to tune out many of the print defects I’m used to seeing on a traditional threaded-rod framed printer.